Description

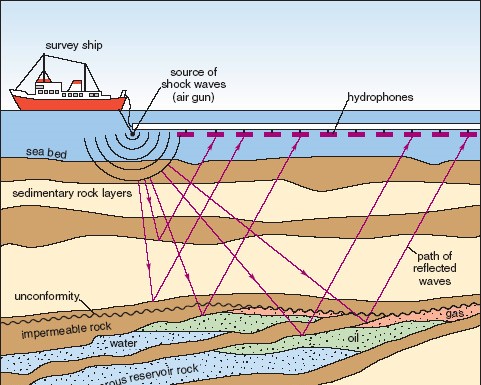

Wellbore Integrity Monitoring Systems are advanced technological solutions designed to ensure the safety, stability, and long-term performance of oil and gas wells. Well integrity refers to the ability of a well to contain hydrocarbons and prevent unintended leaks into surrounding formations or the environment. These monitoring systems utilize a combination of sensors, data acquisition devices, and analytical software to track pressure, temperature, casing stress, corrosion, and fluid movement along the wellbore. They provide early detection of potential integrity failures such as casing deformation, cement sheath degradation, or formation fracturing, allowing operators to implement corrective measures before major incidents occur. Modern systems integrate real-time telemetry, machine learning, and predictive analytics to offer continuous monitoring, automated alerts, and trend analysis over the well’s lifecycle. By ensuring wellbore integrity, these systems enhance operational safety, prevent environmental contamination, and optimize production efficiency. They are critical for both onshore and offshore wells, especially in high-pressure, high-temperature (HPHT) environments or aging fields where structural integrity can degrade over time. Additionally, regulatory bodies increasingly require comprehensive well integrity monitoring to comply with environmental and safety standards. By providing accurate, actionable insights into well performance, these systems help operators extend the productive life of wells, reduce non-productive time, and ensure responsible resource management, making them indispensable in modern petroleum and natural gas operations.

Reviews

There are no reviews yet.