Description

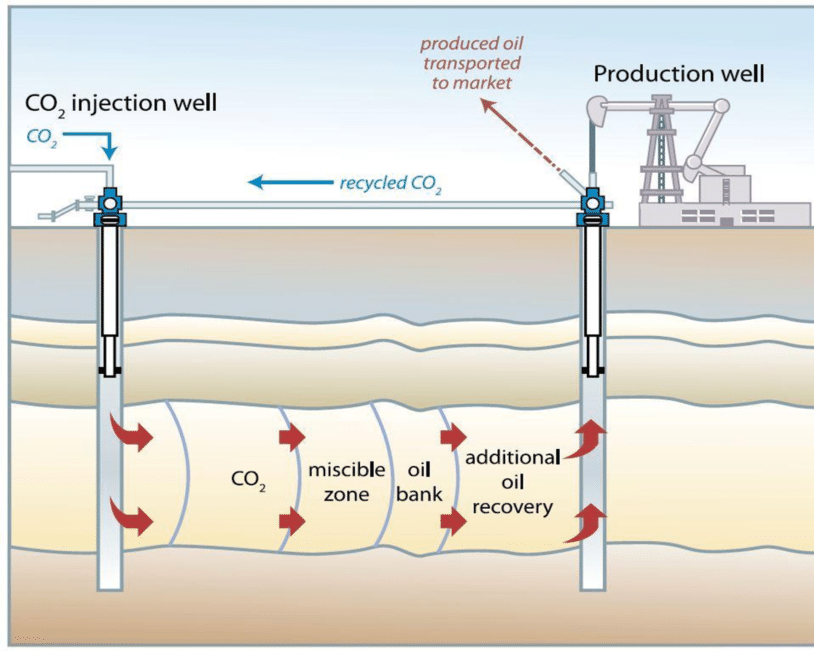

Crude Oil Refining Units are critical components of the petroleum industry, responsible for transforming raw crude oil into a wide range of refined products that meet global energy and industrial demands. The refining process involves multiple stages, including distillation, conversion, treatment, and blending. Initially, crude oil is heated in distillation columns, separating it into fractions based on boiling points, such as naphtha, kerosene, diesel, and heavier residues. Conversion processes, such as catalytic cracking, hydrocracking, and coking, break down heavier fractions into lighter, high-value products to meet market specifications. Treatment and purification units remove impurities like sulfur, nitrogen, and metals, ensuring compliance with environmental regulations and product quality standards. Modern refining units integrate sophisticated control systems, sensors, and automation software to optimize yield, energy efficiency, and safety. They employ heat integration, process monitoring, and predictive analytics to minimize operational costs and environmental footprint. Crude oil refining units also play a strategic role in energy security, providing feedstock for petrochemical industries, transportation fuels, and industrial lubricants. Furthermore, refineries continuously evolve with advanced technologies such as process intensification, digital twins, and AI-based process optimization, enabling higher throughput, reduced emissions, and adaptive operation in response to fluctuating crude types and market demands. Overall, these units are vital for converting a raw natural resource into diverse products that power modern economies while ensuring operational safety and sustainability.

Clement –

Crude Oil Refining Units’ digital tools significantly optimized our refining processes. We saw a marked decrease in downtime thanks to their predictive analytics, allowing for proactive maintenance. The collaborative platform fostered seamless communication across our engineering teams, and their responsive support quickly resolved implementation challenges.

Yemisi –

Crude Oil Refining Units’ digital twins dramatically streamlined our turnaround planning. We identified critical pressure point simulations that would have otherwise been missed, saving us valuable downtime and preventing potential operational disruptions. The support team’s responsiveness was exceptional.

Dupe –

Crude Oil Refining Units’ digital platform revolutionized our distillation tower optimization. We saw a 15% reduction in energy consumption within the first quarter. The team’s swift communication and insightful support navigated complex bottlenecks efficiently, surpassing our operational expectations.

Sadia –

Crude Oil Refining Units’ digital twin proved invaluable in optimizing our naphtha cracker feed. We reduced unplanned downtime by 15% by proactively addressing corrosion hotspots the simulation predicted. The support team’s responsiveness during integration was exceptional; a true partner in enhancing refinery efficiency.

Taiwo –

Crude Oil Refining Units’ digital twins revolutionized our turnaround planning. We identified critical bottlenecks in our pre-flash unit we’d previously missed, shaving weeks off projected downtime. The team’s prompt communication and responsive support were crucial in integrating the model. A tangible ROI, rapidly realized.