Description

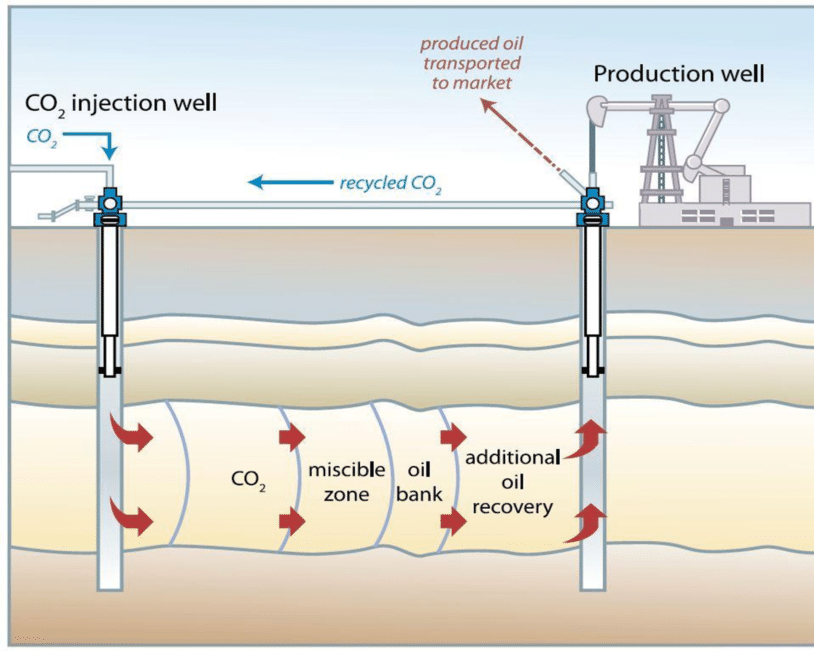

Gas Processing & Separation Plants are essential facilities in the natural gas industry that purify raw gas streams and separate valuable components, such as methane, ethane, propane, butane, and other natural gas liquids (NGLs). Raw natural gas extracted from wells contains a mixture of hydrocarbons, water vapor, carbon dioxide, hydrogen sulfide, and other impurities that must be removed before pipeline transportation or end-use. These plants use advanced processes like cryogenic distillation, absorption, adsorption, and membrane separation to selectively isolate hydrocarbons and remove contaminants. For instance, cryogenic processing cools the gas to extremely low temperatures to liquefy heavier components, while amine-based absorption systems remove acid gases such as CO₂ and H₂S. Gas processing and separation enhance product quality, safety, and commercial value, enabling the production of LPG, ethane for petrochemical feedstocks, and pipeline-quality dry natural gas. Modern plants integrate real-time monitoring, advanced process control, and predictive maintenance to ensure efficient operation, reduce downtime, and optimize energy consumption. They also prioritize environmental compliance by managing emissions, flaring, and wastewater from processing operations. By effectively converting raw gas into high-value products, gas processing and separation plants support energy supply chains, reduce wastage of hydrocarbon resources, and contribute to economic growth in both domestic and global markets. Additionally, technological advancements such as AI-driven process optimization, digital twins, and automated fault detection systems are increasingly applied to maximize recovery, improve operational safety, and minimize the environmental footprint of gas processing operations.

Balarabe –

Gas Processing & Separation Plants” significantly streamlined our NGL extraction. The detailed process modeling accurately predicted separation efficiencies, reducing costly pilot tests. Their team’s quick responses and insightful support ensured seamless integration, boosting our overall refining output by a measurable percentage.

Safiyanu –

Gas Processing & Separation Plants’ significantly streamlined our NGL extraction process. The detailed modeling capabilities pinpointed bottlenecks we’d missed, boosting our ethane recovery by 7%. Their team provided quick, insightful support, ensuring seamless integration with our existing refinery software.

Mary –

Gas Processing & Separation Plants” significantly optimized our NGL extraction. We saw a 15% increase in propane recovery after implementation. Their team’s proactive support and clear communication were invaluable in navigating initial setup challenges, resulting in a cleaner, more profitable product stream.

Amadu –

Gas Processing & Separation Plants” revolutionized our NGL extraction process. We pinpointed inefficiencies we hadn’t seen before. The detailed simulations improved our plant’s throughput by 15%, a direct impact on profitability. Their team’s responsiveness and nuanced understanding of separation dynamics were invaluable.

Austin –

Gas Processing & Separation Plants” significantly streamlined our NGL extraction process. We saw a measurable increase in propane recovery rates, exceeding initial projections. The engineering team’s responsiveness and clear communication during commissioning were invaluable, ensuring a smooth transition and optimized plant performance.